Manufacturing printing plates is a complex process, where defects can sneak in at the various production steps. Imperfect printing plates cause printed material of inferior quality. Since quality requirements in many areas are high and continue to rise, the consequential costs of these defects are high.

Algoscan and Impuls have cooperated and developped a fully automatic inspection system for printing plates. Algoscan is specialized on surface inspection and Impuls has contributed the computer vision know-how. The printing plate is scanned on a highly precise moving table with a high-resolution camera and compared with a digital master. The measurement accuracy is 5 µm with a printing plate of a size of 100 x 110 cm. The inspection system can classify various defect types.

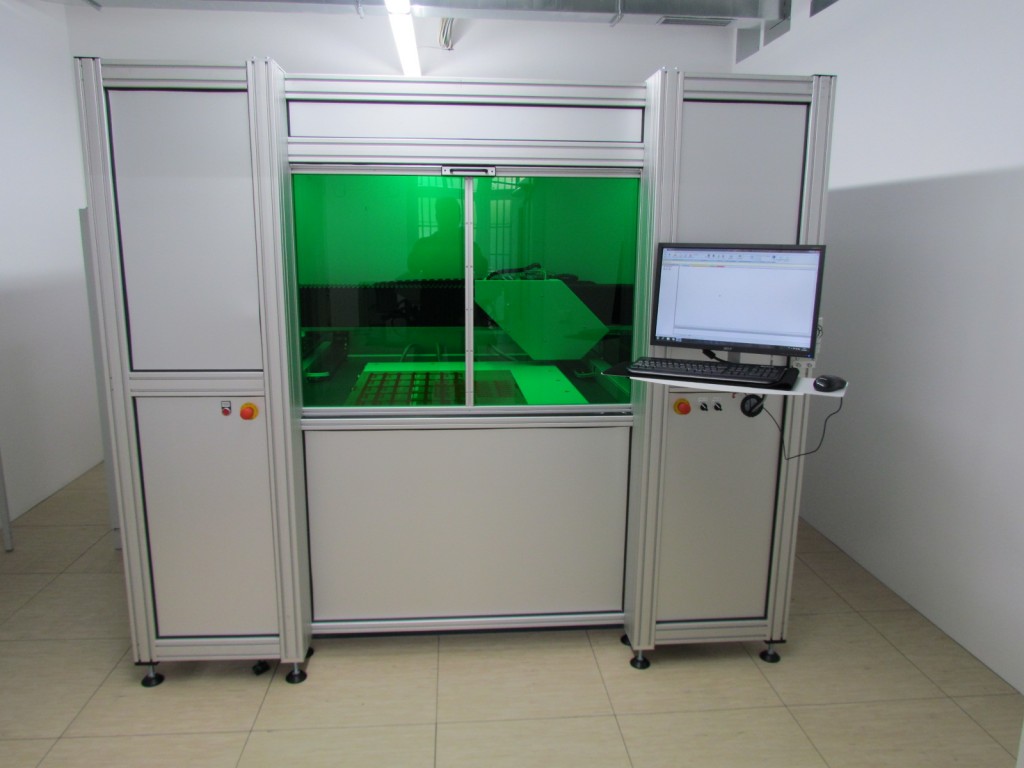

The picture shows the inspection system:

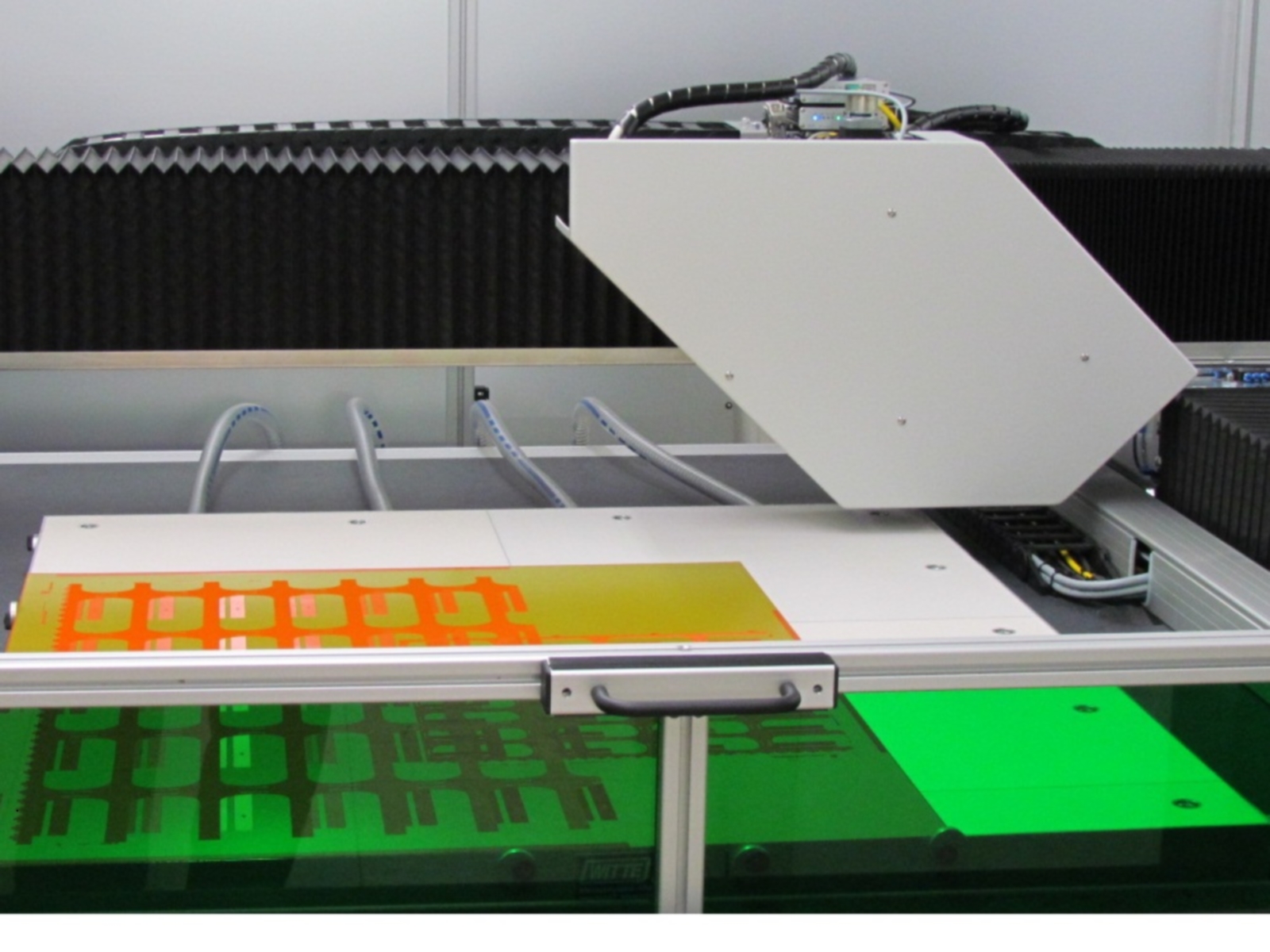

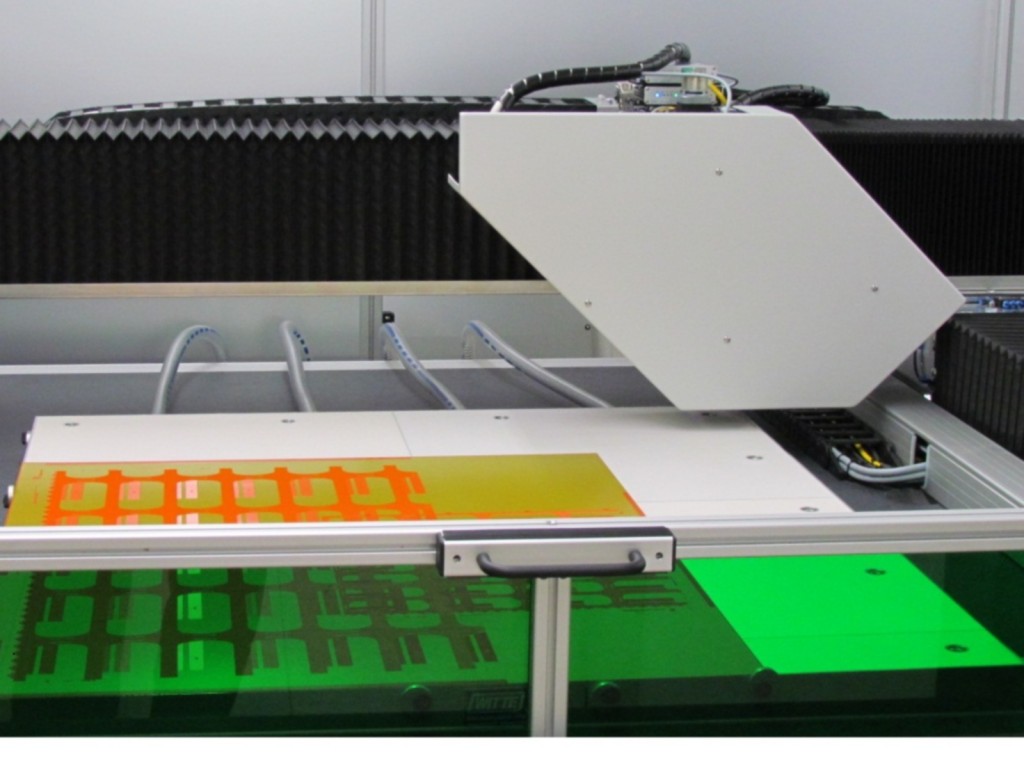

The vaccum table and the optical sensor head:

More information:

Hochpräzises Inspektionssystem für Druckplatten